Hydraulic Bike

THERE ARE GREAT WAYS TO DESIGN A BICYCLE - THIS IS NOT ONE OF THEM

Senior Design Project -- We built a hydraulically powered bike to take to competition in California. A bike for the 21st century, I did electronics and software.

Programming

Wrote all logic and GUI elements including interfacing completely incompatable 3rd party hardware for automatic gear shifting

Award Winning Design

Competed in the national Parker-Hannifin Chainless Challenge winning awards and over $6000 in take-home prize money

Electrical Design

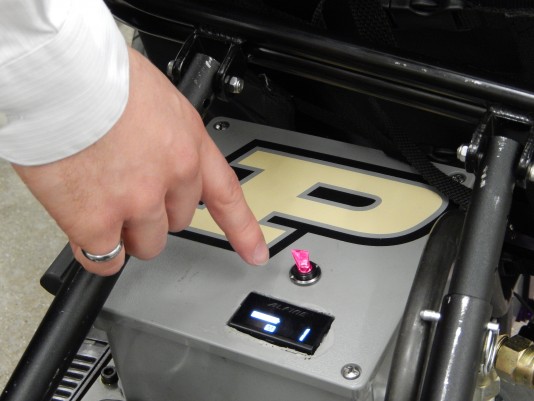

Designed electrical systems from battery chemistry and power distribution to CAN network and custom proto-board component interface

4 Distinct Operating Modes

All electrically controlled by the program (or operator from the control screen interface)

Designed and built by the 2014 Purdue Chainless Challenge team consisting of 8 engineering undergrads (from the ME, ABE, and MDE departments), the Hydrover is the project I’m most proud of to date.

Over 8 months the team brainstormed, ordered, made, assembled, tested and shipped the bike to Anaheim, CA to complete in the annual Parker-Hannifin Chainless Challenge university competition consisting of Sprint, Team Relay, Time Trial and Efficiency races. Each of these races provided different and often conflicting criteria for the design, but a few things we came to near-immediate agreement on were a trike design for stability, the need to include regenerative braking, and to make the bike as modern (i.e. technological) as possible (which is where I came in).

- Hydraulics — Casappa Single and Duplex Gear Pumps and Motor, Parker On/Off Solenoid and Proportional Valves, 2 Parker Bladder Accumulators, Mobil Biodegradable Hydraulic Fluid

- Frame — Custom Aluminum Chassis Extension Plates and Mounts on a TerraTrike Rover

- Gearing — Dog Gear to disengage Regen. Pump, custom Misumi Gear Trains

- Automatic Gear Shifting (subsystem built by me on top of Shimano’s Alfine Di2)

- Cosmetics and safety — manual braking, gear guards, color scheming, component placement, and underglow (see videos)

- Electronics — Sensors (RPM/Gear Tooth, 3 Pressure, Regen. Trigger (on brake handle), Interface Buttons), Valve Actuation, LCD Screen w/Custom GUI and Control Program (displaying various bike operating modes and statuses), NiMH Batteries, Custom (made by me) signal conversion PCB

Hydrover = Hydraulic TerraTrike Rover

- Interface PCB — designed, prototyped, tested, and iterated completely custom circuitry to interface between disparate proprietary subsystems using optoisolators for signal transfer

- All Electrical — design, layout, and assembly (as assisted by a teammate)

- All Programming — system actions/states, GUI, and test-based optimization

- Shop Experience — including band saw, drill press, CNC mill, pipe bending, assembly, terminology, and tool use

- Troubleshooting — all electronics, software, and behavior issues and predictions

- Presentations and Marketing — critical design reviews, demo events, publicity, logistics

- 1st Place in these Categories: Most Innovative, Team (Peer) Choice

- 2nd: Overall, Best Paper and Presentation

- 3rd: Sprint Race, Manufacturing and Workmanship

- 4th: Sprint Team, Time Trial, Efficiency

- Total Cash Winnings: $6,075.00

- On-campus Demo Event – Very Successful (most of the MDE department came – Thanks Guys!)

- Mechanical Engineering Senior Design Project Fair – Lots of “ooh that’s cool”

This project is a good example of the way I operate; I joke that I majored in “Red Tape Wrangling.” In order to participate in this project as my senior capstone class (in lieu of the more the more theoretical projects or those that were being planned for my major’s capstone class) I obtained every override in the system (save for being on the wrong campus). The official class section was listed under a different major, by permission only, at a time I had a conflict, etc, etc, all of which required multiple visits between advisor and administrator offices. Luckily, having done simpler versions of this process for previous classes, I knew to work all this out the semester before. Let the record show that I don’t let such obstacles as “the way it’s usually done” get in my way.

The following video was produced by the Multidisciplinary Engineering departmental for marketing purposes as this project was something bigger than what other students had done in the past. It is currently shown to all First Year Engineering students as part of the “What MDE is” presentation and was shown to 2323 students Fall 2014 semester alone.

Short video of initial testing as shown as part of our presentation:

Our final presentation slides outlining the details of our design: Google Sheets

Ongoing History of the Purdue Teams under Dr. Andrea Vacca: History

A couple of my teammates presenting the project at the ABE senior design review: YouTube

Congrats to the Purdue 2017 Team! The first Purdue team to take home the gold: YouTube