Work History

Reverse Chronological Order

BBS Automation

Bespoke Business Solutions

October 2015 - July 2016

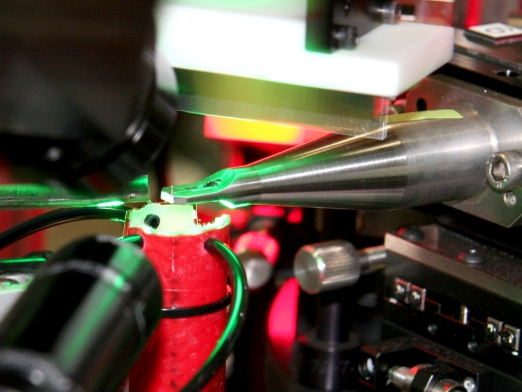

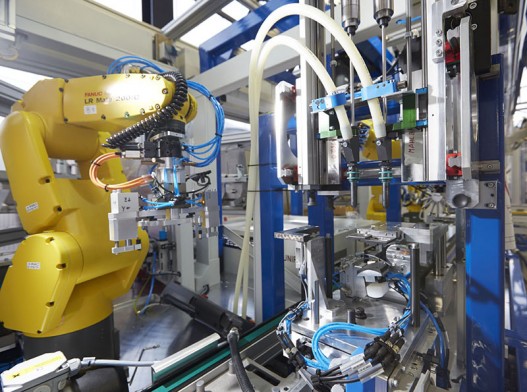

Outside Chicago, BBS designs and builds custom assembly automation machines. I worked closely with individuals from every department, breaking down communication barriers between them, from VP to machinists, to solve problems before they happened. While there I created new and updated existing mechanical and electrical designs and assisted in integration of controls hardware and software for a variety of large machines across a variety of industries.

o Lead US-based team consisting of a new college grad and a senior engineer close to retirement

o Project interfaced US, German, and Malaysian sister companies (first of its kind experiment)

o Managed project across 2 time zones and 3+ languages while solo in Germany.

o Project completed on time and under budget despite lack of consensus about responsibilities of various groups

o Department of One – Reported directly to Director of Engineering

o Designed custom mechanisms, discovered flaws in and integrated changes to electrical system, optimized controls logic, and constructed proof-of-concept prototypes

o Actively worked with individuals from every department almost every day – going well above and beyond the usual levels of communication to improve design and ease of assembly, as well as reduce rework costs by avoiding problems before they exist

o Updated electrical schematics to reflect build changes and prepared a large system for UL inspection

o Became Cognex Vision Certified

o Assisted in modernization of The Toymaker 3000 at Chicago’s Museum of Science and Industry

o Designed novel singulation mechanism for wires including functional mock-up (first task upon hire)

o Specified Mitsubishi Robots for new work cells based on speed, reach, and load

o Programmed and simulated industrial robots to test and minimize process (takt) time

o Researched and specified 3rd-party hardware for customers including Calibration Well for Brachytherapy ( implantable radioactive “seeds”) and shielding

Vizient

Manufacturing Solutions

June 2014 - August 2014

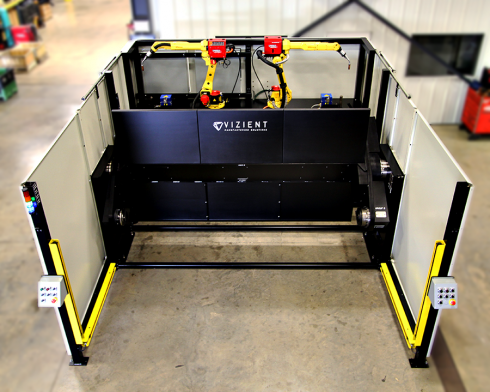

Short-term work in the Quad Cities region of Iowa checking, approving, and modifying CAD models and drawings for robotic welding workcells. This required use of my drafting, modeling, and assembly skills in Creo 2.0 as well as an understanding of appropriate manufacturing methods. This included modifying parts/assemblies before checking them for real-world assemblability and then promoting them within the PDM package Windchill to production.

Rosen Center for Advanced Computing (RCAC)

Purdue University

February 2013 - May 2014

Student employment concurrent with being a Tour Guide. Installed and maintained both hardware and low-level software on thousands of compute nodes for the various supercomputing research networks centered at Purdue University including those part of Purdue's Community Cluster Program. These supercomputing clusters allow Purdue students and staff to run massively parallel applications as well as serving off-campus researchers like CERN (including the Large Hardon Collider, specifically the CMS experiment).

Office of Admisisons

Purdue University

May 2012 - May 2014

Student employment during two of the hottest summers and coldest winters on record as a Tour Guide representing Purdue University to potential students and other non-student guests. This included speaking to wildly varying groups, often in inclement weather, ensuring accurate delivery of key points. Varied tour path, presentation tone, and details for an internationally varying audiences with varying physical abilities and weather tolerances. Position lead to a professional interest in knowing more about the campus including little-known lore, events (like the "tank scrap"), and tour locations (like the supercomputers (see RCAC), nuclear reactor, and particle accelerator).

All Vizient, BBS, and some RCAC imagery courtousy of their respective sites. Please don't sue me.